Noninvasive Water Pipe Data Collection

Date:

Publication:

Juneau benefits from pipe condition assessment licensing solution for water utilities

The Alaska city and borough of Juneau produces and distributes 1.2 billion gallons of water annually by drawing from separate and redundant ground- and surface water sources. Around 50 pump stations deliver potable water via a network of over 180 miles of pipe, directing into a series of reservoirs that in turn feed thousands of hydrants and terminal water distribution connections.Most of the water for downtown, in the hospital area, and on Douglas Island comes from the Last Chance Basin Aquifer. All areas north of the hospital primarily receive surface water out of the Salmon Creek Water Filtration Plant.

The city’s public drinking water system is one of over 153,000 similar public systems that provide potable water across the U.S. Approximately every two minutes, a pipe breaks in the U.S. amounting to around 2.1 trillion gallons of water lost every year. Since most of the nation’s infrastructure was built between the 1890s and 1940s, it’s not that surprising. The city of Juneau has one to two pipe breaks per year, at a repair cost of $200 to $1,000 per foot.

The city is undergoing a replacement program of its water mains to maintain reliable and consistent service to its customers. “Pipe replacement decisions are made based on a comprehensive look at break history, age, location and ePulse results,” says city of Juneau Project Manager Abner Miller.The city chose to license ePulse, an acoustic velocity testing technology by Echologics, to noninvasively provide critical condition assessment information and simultaneously check for leaks using its own utility staff to collect field data. This was initiated to improve capital budget spending and reduce the replacement of water mains in good condition, as well as establish a baseline understanding of pipe condition.

“We first used ePulse in 2022 and found the results to be very good,” Miller says. “It is a noninvasive, nondestructive method of data collection for pipes in the ground and there is no need to stop the water service or alter traffic.”

In 2022 the city tested over a mile of water distribution pipe in the South Douglas area. Historically, Douglas Island experiences a higher water table and significant runoff from the mountains that accelerates the corrosion of the ductile iron water pipes. The entire area’s water network was prioritized by the water department to be replaced with HDPE within the next five years.

“It’s only practical for us to replace approximately 1,500 feet of water pipe per year, so the goal was to identify the particularly bad segments so we could prioritize projects to replace those segments accordingly,” says Nick Druyvestein, engineering associate at the city of Juneau.

Acoustic velocity testing

The city adopted AV testing of its water mains as a first-level diagnostic approach of its network. To collect the required data in the field, city staff attached acoustic sensors to existing appurtenances such as valves or hydrant isolation valves. An acoustic wave is induced in the pipe externally by gently tapping on a fire hydrant. The velocity of the acoustic wave is measured as it travels through the pipe segment

The acoustic velocity is calculated based on the sensor spacing and time delay between the measured acoustic signals. The average structural wall thickness of the pipe segment is calculated from a theoretical model of its relationship with the acoustic velocity, the pipe diameter, Young’s modulus of the pipe wall and the bulk modulus of water. Average wall thickness results are most suitable to evaluate the remaining service life of water pipes for long-term planning of replacement needs.

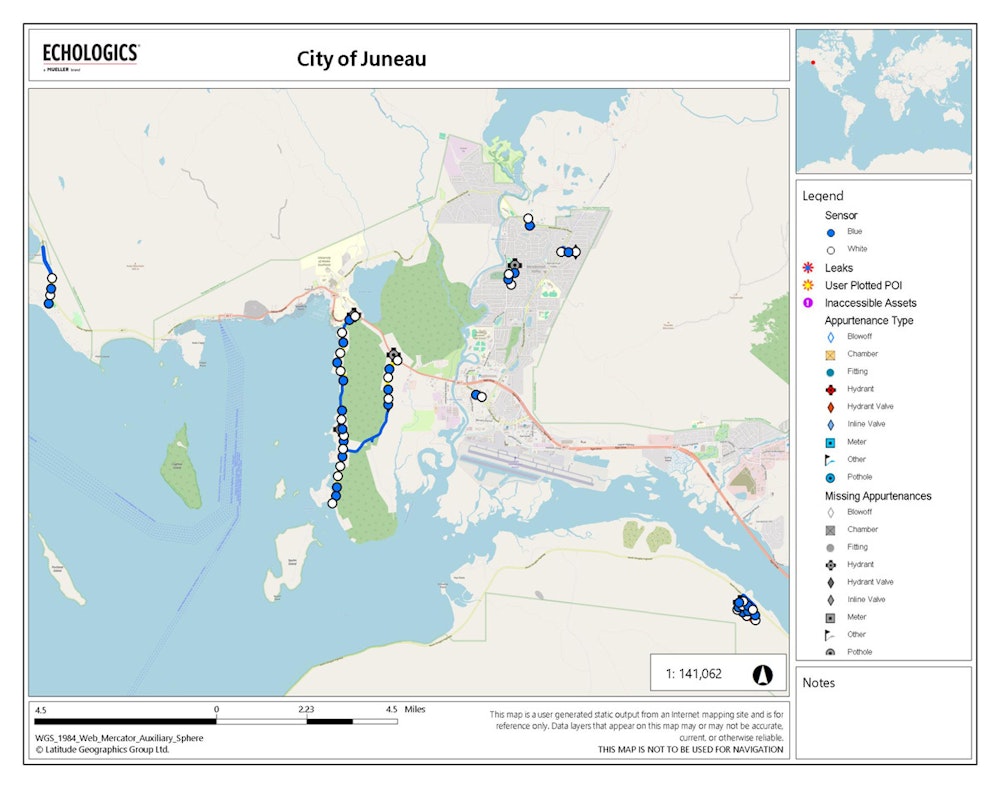

GIS mapping

The city started GIS mapping about 10 years ago, primarily for fire/public safety purposes. As part of the condition assessment, the city needed to refine its GIS of the water system and develop maps to visually display the assessment results.

“We started to ramp up the GIS utility work in 2023 with the intent to build out our water system in GIS as we collected data for ePulse,” Druyvestein says.

Implementation

As Juneau is somewhat remote, the utility chose to reduce the costs of bringing in field crews to survey pipe, and instead had staff undergo a three-week training program on how to effectively use the technology. This included classroom training and real-life field data collection on the city’s water network. The license of this technology allowed the city to collect field data on its own schedule and then send the data to Mueller for analysis. The city of Juneau is the first utility to license this technology to enable its own staff to collect the acoustic data in the field.

The pipe segments that were marked for condition assessment were varying lengths and sizes, ranging from 6- to 18-inch ductile iron pipe. Since the adoption of this technology, the city has conducted two condition assessment projects totaling about 6 miles of water main or 3% of its network.

ePulse provides a report on the mean hoop thickness of each pipe segment, so that the city can prioritize where it will start replacement. The city plans to continue testing about 5 to 10 miles of pipe every year in order to complete the assessment of 100 miles of ductile iron pipe. Data obtained through this condition assessment program will guide capital budgets and reduce risk by helping prioritize pipe replacement in areas with a higher level of pipe wall degradation.